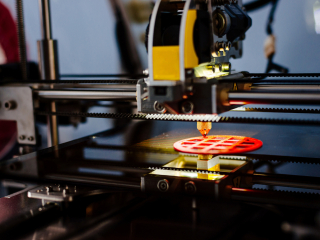

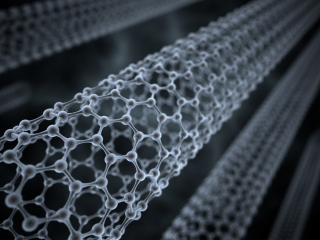

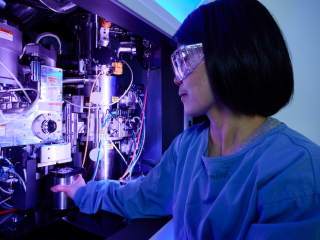

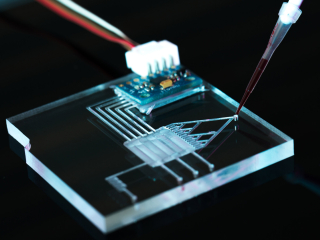

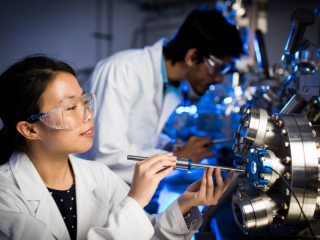

- Advanced energy materials

- Decarbonising the grid

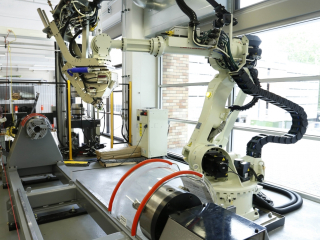

- Electrification of industries & transport

- Energy asset valuation

- Energy & environmental markets

- Energy meteorology

- Geothermal energy

- Heat mitigation for cities

- Hydrogen production & storage

- Intelligent monitoring of electricity grids

- Marine energy

- Microgrid modelling & simulation

- Next generation solar PV & systems

- Recycling & MICROfactories™

- Renewables, energy efficiency & emissions policy

- Renewable energy integration, systems & storage

- Structural supercapacitors & batteries

- Sustainable fuels & chemicals manufacturing

- Zero & positive energy buildings

Didn’t find what you’re looking for? The above topics are examples of our expertise but not an exhaustive list. Get in touch to learn more about our capabilities and how they could further your business goals.